Requirement:

Irrigation system suited to apply water and feed requirements to a total area of 11.44 Ha, with 5.44Ha installed now and another 6Ha installed the following year.

Water Source & Field Locality: Water source is a well point near the main farm with limitation of 18m³ - 20m³/hr, with table top system located some 700m away. Water to be acid treated to correct pH value. No power infield, but limited power available at well point.

System Application:

2l/hr Netafim HCNL PCJ Drippers c/w 50cm lead & “s” stake applied 4 per m (4 drippers per bag) on 20mm LDPE Laterals. 20mm LDPE was supplied pre-punched for ease of applications, with drippers inserted by hand on site. Due to long tunnel lengths, section headers were applied to split the tunnel in half with flow distributed either side of the header. DNLs locations were lazer levelled and applied in lower areas to prevent drain down of system.

System was split into 6 irrigation sections ranging from a flow of approx. 36m³ to 55m³/hr dependant on tunnel area lay-out. A further 6 or 7 sections are to be applied when expansion is put into place the following year. Each section is controlled by Dorot 3” PR 9VDC Pulse Solenoid Valve linked back to the Netafim NMC Pro Controller at pump point via a single 2-core cable that runs the length of the buried main line.

System main line comprises 125mm PVC pipework which spurs into 110mm PVC closer to valve section points. A 125mm PVC Lever Valve is currently in place along the line to the area of expansion later on, to allow ease of additional main pipe to be laid.

The pump point is sited in a container located at the highest point in the field, roughly central to the tunnelled area. The pumping point comprises an 18.5kW Vertical Multistage Variable Speed Drive pump unit drawing water from a 45’x 10” Galvanised Steel Tank. The tank was sized to hold just over one day worth of water, and being the biggest an Anti-algae cover is sized for.

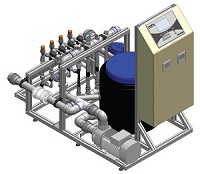

Around the suction and discharge of the pump unit is placed a Netafim Fertikit S Nutrigation Rig. This unit comprises of an NMC Pro controller being the “command centre” of irrigation control; watering, monitoring of EC and pH in application across the system in accordance to user defined settings. 2 irrigation triggers are set in this system: firstly, a dry contact to pump start as the unit is powered by generator, and secondly, Radiation Sum to trigger irrigation according to measurement of radiation in Joules per cm².

The Fertikit S consists of 4 x 300L/hr Dosing Channels (Venturi) for feed/fertiliser injection + 1 x 40L/hr Dosing Channel for acid application. Currently the system only uses two of the feed dosing channels, with the additional two in place to double dose if required. The Acid Channel is to trim the pH value of water from that already treated in the storage tank (discussed below).

The “Feed” Dosing Channels draw from two IBC containers located in the storage container alongside the pump/rig set-up. These IBC containers are agitated by means of an air blower mounted on the wall to ensure good mixing of granular feed in water.

The 45’ Galvanised Storage Tank located next to the container is filled by means of a submersible pump located in the well 700m away near the main office. Filling is controlled by means of float switches on the tank, with cable leading back along the pipe to the well point. During filling of the tank, an Acid Dosing Unit injects acid into the pipe prior to filling the tank and tests the value a little further down the pipe. This is to correct the pH value of water from the well to a more desirable value required during irrigation purposes.

Overview:

In applying the system in such a manner, the grower has overcome the scenario of having to supply a large table top area from a source of little power and a limitation on the amount of water that is available in a pumping hour from the well point.

The application of the Netafim Rig and NMC Pro Controller gives the grower a large range of options and the flexibility to water, feed and fertilise to plant requirements with added peace of mind.