Requirement:

Move towards pot production of Raspberries in an effort to reduce soil production and draw away from soil sterilisation methods being employed in such applications. Fields were also affected by slope.

System Application:

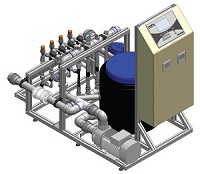

After successfully specifying the Netafim Netajet series of EC and pH rigs during 2008 on other sites owned by The Farm, it was only natural to base the new system around the same technology. The first field considered on the new farm extends to 3 Hectares and is home to raspberry plants grown in 7.5 litre pots, three rows per Spanish tunnel. Each pot is served using a single Netafim PCJ dripper. The crucial element of a system like this is to ensure that the pipework remains full inbetween irrigations. This is the only way to achieve uniformity of water application and is the big difference between a glasshouse and a “field”. New Leaf is the only company to my knowledge that uses a laser level to ascertain accurately the topography of each site. Indeed, technology has of course moved on and so in future GPS will be used more and more to improve the quality of our work. After surveying the site it was possible to position “Non Leakage” valves into the dripperlines to effectively divide each run into sections of height that the drippers can withstand. In this way it was possible to calculate a need for 320 “Non Leakage” valves over the whole 3 hectares and provide the farm with a simple plan showing the position of each one.

It was decided to work to a much larger flow rate than that strictly required for this field alone, as it is an unspoken rule to ensure capacity is available for future needs and developments. A driving factor in this is the way the Netajet system works. As it simply diverts water from the main irrigation line and doses it with fertilizer and acid to the required volumes, re-injecting back into the same length of pipe, exactly the same unit can deal with flows from under 20m3/hr to over 50 m3/hr, only limited by the rate that the injectors can draw in feed. This meant that it was no more costly to work at 40 m3/hr than it was to operate at half the flow rate. Only two solenoid valves were thus required.

Overview:

Once a main of 110mm PVC was laid and an 11kW Lowara variable speed pump was wired to the Netajet rig, all was ready to begin irrigation. After a few weeks the overall Irrigation Manager for the farms decided to link The Farm’s original irrigation system into the Netajet. This time however he decided to opt for the Netafim Radionet control system to operate solenoid valves rather than the “Singlenet” 2 wire system used on the pot grown raspberries. This option is attractive, especially where pipes were installed many years ago. In those days the automatic timing of valves was seen as a luxury and so cables were not buried with the pipes. To install cables retrospectively can be costly, and that’s assuming that there aren’t roads, rivers, or neighbouring farms in the way!

The next development is to install Netafim’s Irriwise crop monitoring technology.