Requirement:

Planning and implementation of a staged system development, allowing for future expansion.

System Application:

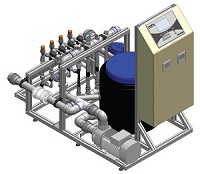

The first decision to be made was sizing the duty point of the new irrigation system. In order to give capacity for future expansion and the possibility of irrigating some of the neighbour’s crops from the same system, a nominal flow rate of 80 m3/hr was selected, with a little extra available for backwashing a filter. In the past each irrigation block had been sized to approximately 20 m3/hr and so it was necessary for the pump to cope with flow rates ranging from 20m3/hr to 80 m3/hr in 20 m3/hr increments. This approach gives the flexibility to operate sprinklers for establishment, raised bed strawberries, and substrate crops all at the same time, over or underlapping times in whatever combination is required. The only way to make this work was to use a Lowara multistage pump on the shore fed by a drainage submersible pump in the reservoir. A single borehole type pump in the reservoir would have cooling problems at the lowest flow rates and so was ruled out at an early stage. The next problem was controlling the 30kW motor that drives the Lowara pump. No easy task as we also need the pump to react to changing demands automatically without connection by wire to the irrigation systems around the farm. The only option was to use a Unico variable speed drive linked to a digital flow switch as other variable speed drives on the market, although very good, do not have the vast array of features and options that this dedicated irrigation unit has. One of these important features is that as the flow builds the set pressure can increase. This will overcome the additional pressure losses incurred at higher flow rates. During 2009 the pumping system is powered from a generator, but for next season mains power will be laid on.

Of course thorough filtration is essential and so it was natural to opt for a Filtomat self cleaning screen filter with 4500 cm2 screen, especially as the farm had previously used a smaller version of this same unit to great effect.

It’s all very well having a pumping system capable of high flows, but if the rest of the system isn’t designed to match, then it simply won’t work. The existing 4” high pressure main was not suitable by itself, but by adding one more section on the far side of the wood we made it into a “ring main”, instantly doubling its capacity to deliver water from the reservoir to the fields.

A Netafim Fertikit EC and pH rig with a 20 m3/hr capacity is plumbed into this ring main. This means that the rig is some 1000 metres away from the pump delivering the water. As the area under substrates increases over time additional rigs will be installed around the farm, but for now this selection of unit gives a sensible cost in relation to the relatively small area under production at this initial stage. One hectare of crop is irrigated as two irrigation blocks controlled by the rig’s NMC Pro controller.

Solenoid valves are positioned with the rig, with the site adjacent. Five rows of tabletop are housed inside 8.6 metre wide temporary tunnels. One-metre bags are irrigated using Netafim non-leakage drippperlines delivering four drip points per bag. In order to provide reliable sealing of the system the drippers were inserted into the pipe at Netafim’s Dutch factory and transported to the farm immediately. Hand punching pipes is costly but more than anything, unreliable. Any drainage of the pipework inbetween irrigations has a negative effect on irrigation uniformity, and thus on the uniformity of the crop.